Infrastructure

Sponge Iron (DRI) Unit

- 300 TPD Sponge Iron Plant:

- State of art, 3 numbers computerized Rotary kiln for Iron Ore processing & manufacturing of Sponge Iron

- Backed up with Coal handling and Captive Power

- Annual capacity : 1.5 Lac M.T.

Ferro Alloy Plant

- 2 nos. 9mVA Sub-merge Arc Furnace

- Ferro Silicon, Ferro- Manganese, Ferro Chrome and Silico Manganese

- Annual capacity: 0.5 Lac M.T.

Steel Melting Shop

- 6 nos. 15MT each capacity Steel Melting Induction Furnace backed up with Ladle Refining Furnace, completely computerized & automated 3 stand Continuous Billet Casting Machine (CCM) with Automatic Mould leveling & speed Control System

- Annual capacity : 3.5 Lac M.T.

Hot Rolling Mill Division

- High efficiency totally automated and computerized TMT Rolling Mills with walk-in type extra long Cooling bed to manufacture high quality TMT /QST Bars in sizes: 8 -32mm dia in Grades Fe-500, 500D, Fe-550D & 600 as per BIS-1786:2008

- Wire Rod (upto 12 mm dia)

- Annual capacity 2.4 Lacs M.T.

Rain Water Harvesting System

- 9 million liters Rain Water Harvesting System at Plasto Steel Park, Barjora, Bankura

- As a part of Noble Notion "SAVE WATER- SAVE LIFE"

- To utilize natural Rain Water for captive process purposes

- To support the world wide water scarcity & also the environment & geological condition, more particularly in this entire District

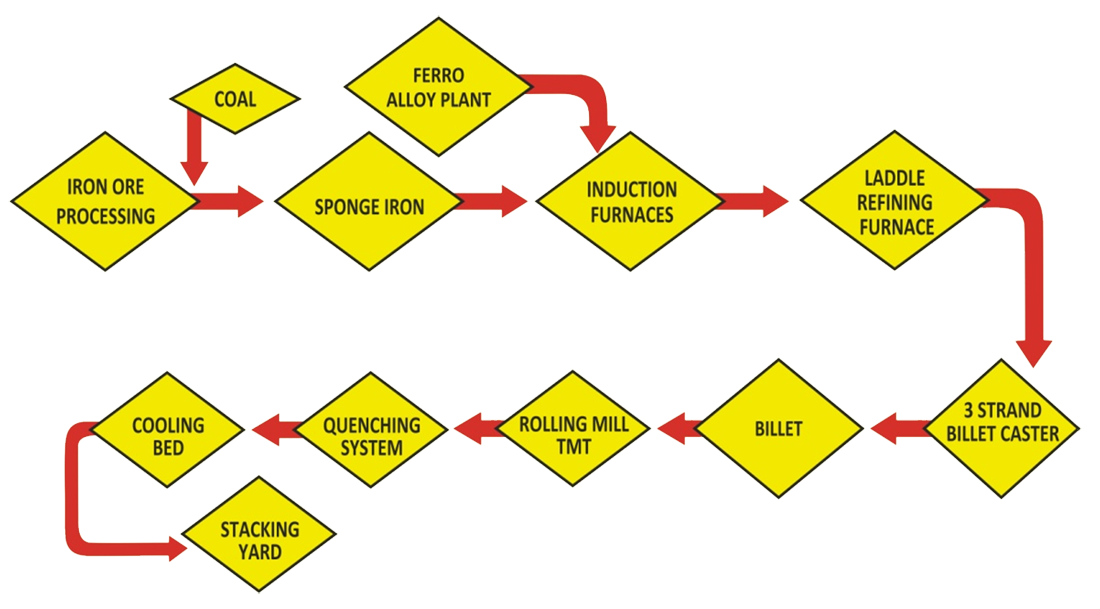

Process Flow Chart

- Integrated Steel Manufacturing