TMT Bars

Our Worldclass Technology

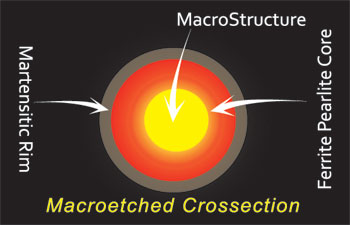

BDG6/TORCON TMT steels bars are based on latest technology & design which guarantees the properties to produce as per international standards. German BST 420 S/500 S of DIM 488, British Gr. 460 of Bs 4449-1988 Egyptian Standard 262/1988 Gr. 36/52 and 40/60, Fe 415, 500, 500D, 550 & 600 as per IS:1786/2008,JIS.G.3112 1975 SD 30, 35,40,45 & 50 Swiss to par 550 S of SIA 162, French Fe E50 of NF A35-016. High strength reinforcement bar in grades of Fe 415, 500, 500D, 550 & 600 as per IS:1786/2008, that achieve their properties by on-line computerized controlled thermo processing.

Our Special Features

Strength and Elongation:

Higher strength and better elongation is a unique feature of BDG6/TORCON TMT bars. Designed to be much stronger than conventional bars, BDG6/TORCON build's a safer and stronger concrete structure with laser quantity of steel with a great savings over the market conventional requirement. BDG6/TORCON guarantees excellent Weldability, Ductility and Bendability. Tapered edge of BDG6/TORCON TMT bars provide better Weldability that help in making high strength connections with little overlap. Due to its low carbon & high manganese content, these bars, can withstand better bending and re-bending without any reduction in strength.

Earthquake Resistance (EQR)

For earthquake resistance, TMT bars structures need to have balanced stiffness, strength and ductility between its members, connections and supports. BDG6/TORCON TMT bars provide very high strengths with comparatively higher elongation values and better ductility, making them more earthquake resistance.

Heat Resistance

Test result for BDG6/TORCON TMT bars, have shown no loss of strength upto 500 degree C. At a temperature range of 550 degree C to 600 degree C, the yield strength decreases by 20N/Sq mm only. That is why BDG6/TORCON TMT bars can be used easily in constructions prone to fire hazards.

Corrosion Resistance (CRS)

BDG6/TORCON TMT bars are more corrosion resistant than normal CTD bars. The fine layer of scale forms a protective layer, thereby preventing further corrosion, where as in CTD bars, this initial layer of scale falls down during twisting. Corrosion resistance can be further improved as per customer needs, by altering material chemistry.

Quality assurance is inherently followed in every step of process

- Quality product, timely delivery, and other services

- Economy-cost saving in buying our product

- Commitment - timely delivery at all places

- Customer satisfaction - Assured supply, your peace of mind

- Safety for all

- Customer preference - at all times

BDG6/TORCON TMT CHEMISTRY

| BDG6/TORCON | BIS | |

|---|---|---|

| Carbon max % | 0.25 | 0.25 to 0.30 |

| Manganese % | 0.5 to 1.2 | - |

| Sulphur | 0.030 to 0.050 | 0.040 to 0.055 |

| Phosphorus % | 0.030 to 0.050 | 0.040 to 0.055 |

| Carbon equivalent | 0.29 to 0.38 | 0.27 to 0.42 |

BDG6/TORCON TMT PROPERTIES

| YIELD(min N / sq mm) | UTS (min N / sq mm) | ELONGATION (min %) | ||||

|---|---|---|---|---|---|---|

| BIS | BDG6/TORCON | BIS | BDG6/TORCON | BIS | BDG6/TORCON | |

| Fe-415 | 415 | 450 | 485 | 550 | 14.5 | 25 |

| Fe-500 | 500 | 540 | 545 | 600 | 12.0 | 20 |

| Fe-500 D | 500 | 550 | 565 | 600 | 16.0 | 22 |

| Fe-550 | 550 | 580 | 585 | 650 | 10.0 | 16 |

| Fe-550 D | 550 | 590 | 600 | 675 | 14.5 | 18 |

| Fe-600 | 600 | 620 | 660 | 680 | 10.0 | 16 |